Production of Food

Supplements in Tablets

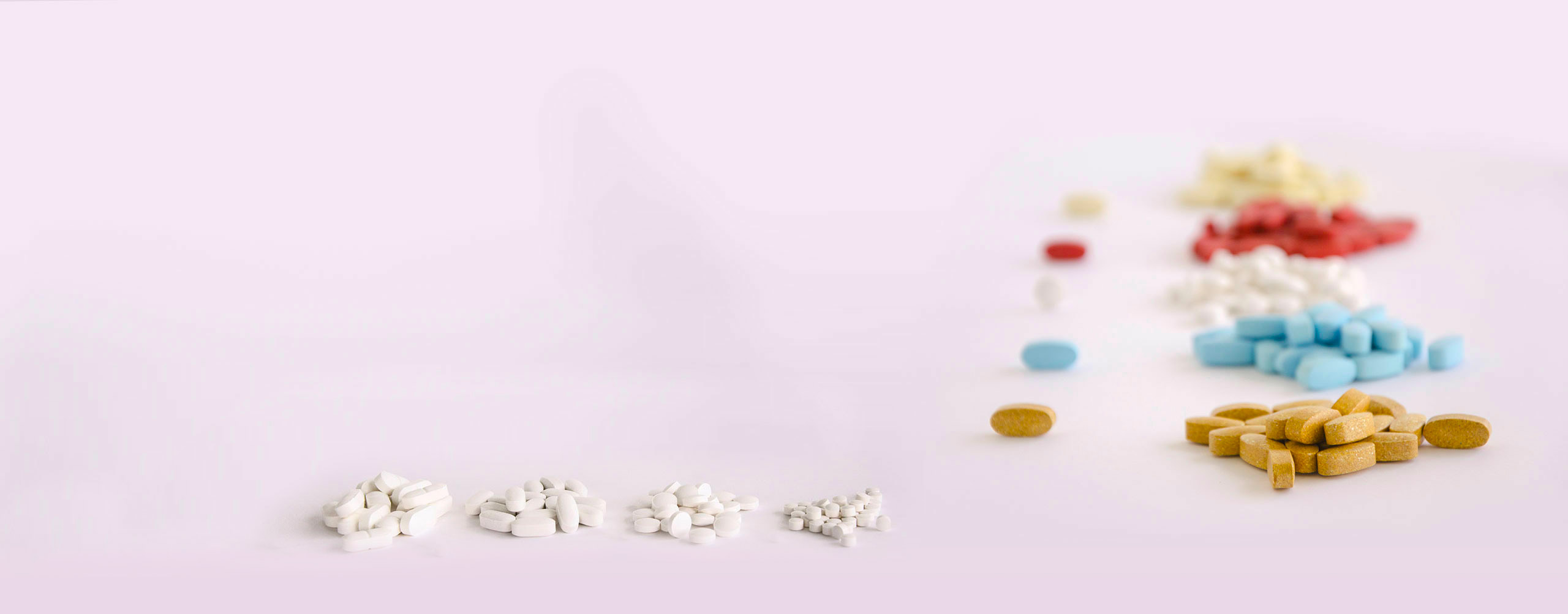

EUDINAMIS is specialised in the production of tablets of various shapes: oval, convex, shaped, round convex, flat round and shaped round.

The used manufacturing technology, combined with the excellence of raw materials, guarantees a product of the highest quality.

The tablets can be coated through a filming process in order to improve their aesthetic appearance (colour, smell, taste) or to obtain an enteric coated product

The shape of our tablets.

The tablets can be packaged in jars (available in various sizes and colors) or in blisters.

The production of food supplements in tablets can have the following formats

Oval format: 19.3 x 9.1 mm

Bombed format: 25.0 x 9.1 mm

Shaped format: 21.0 x 10.0 mm

Bombed round format: 11.2 mm (diameter)

Tondo flat format: 16.0 mm (diameter)

Bombed round format: 6.1 mm (diameter)

| Formats | Size |

|---|---|

| Format round | 19.3 x 9.1 mm |

| Format convex | 25.0 x 9.1 mm |

| Format shaped | 21.0 x 10.0 mm |

| Format rounded convex | 11.2 mm (diameter) |

| Format flat round | 16.0 mm (diameter) |

| Format rounded convex | 6.1 mm (diameter) |

In Eudinamis all pharmaceutical formats are produced so that they can meet the three fundamental requirements, such as effectiveness, safety and quality.

We have always committed to obtaining an optimal formulation, in order to offer only the best, starting from a high quality raw material, which reflects the requirements of the high standards that we are looking for and demanding from our suppliers.

The tablets, solid preparations intended for oral administration, represent one of the formats by us most produced;Their manufacture is a complex process with multiple stadiums to which we dedicate maximum attention.

Our collaborators involved in the formulation ensure that the tablet is correctly shaped.

The priority is in fact to obtain a product that contains the maximum amount of active ingredient.

To it is added the right dose of excipients, necessary so that a correct flow of dust can be obtained in the processing phase and a granulometry that is suitable for the compressing phase, to obtain a good level of composition, as well as the control of the delivery phase at the appropriate time, maintaining correct integrity and chemical stability.

Furthermore, during the formulation phase, the goal of creating resistant tablets to mechanical shocks due to impacts, even during packaging, which are characterized by a uniform unitary weight, and which finally are lacking in defects once in the hands of the final consumer, is well focused.

It is consequently very important for us that our product present a high degree of palatability and ease of intake.

For this reason, the tablets are commonly shaped in oval, rounded, shaped, rounded, flat and shaped round forms, thanks to our compressive machines, depending on the customer’s needs, to which we guarantee maximum flexibility and speed in the delivery of the finished product.

All our employees involved in the production sector are trained to operate according to GMP practices, following the standard procedures that govern their activities during the production phases.

Coated tablets

Coating of nuclei:

– with natural colors

– with glossy

– with gastro-resistence (enteric coated tablets)

Stay connected

with Eudinamis.

Write to us, contact us or request a quote

Quote

Get a quote